Stick Tech

Materials

There can be multiple different materials used in composite hockey sticks, from the most basic, pure fibreglass sticks up to the most complex high carbon, vibration controlling, super lightweight Olympic level items. This section details the nature of all the materials that are used across the Mercian range, what they do and the effect they have. Each stick on the website has a summary of the materials in them and can be related back to these more detailed explanations.

CARBON FIBRE

One of the most common questions asked by the consumer is ‘how much carbon?’ with the perception that more is better. That is far from the truth, so to shed a little light.

Firstly the quality of carbon (manufacturing point) is important. Toray (Japanese) Carbon is often considered the best, but Carbon from Germany, Scotland and South Africa (to name a few) are all high-quality. Sticks are usually made in Pakistan and most major brands will import Carbon into Pakistan to make sticks. Local made carbon is not usually as good. But it is difficult to know if a brand uses imported carbon.

The number of filaments in the carbon fibre is relevant, 1K, 3K etc relate to the number of filaments of pure carbon within a fibre or ‘tow’. 1K is used in aeronautical industry and electronics. 3K and 6K are commonly used in sport as they have the right combination of weight and strength. Anything over 6K is very dense and too heavy for sports equipment. Again this isn’t a common line of questioning from the consumer but may come up.

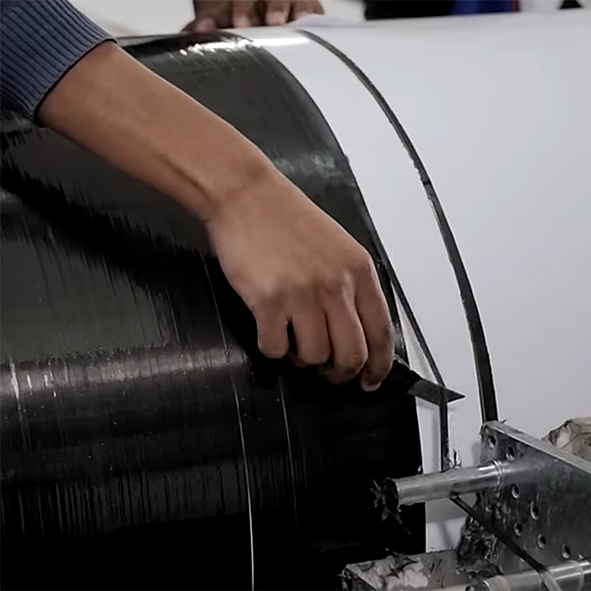

Carbon fibres are a straight line material and so provide stiffness in a single direction. To provide stiffness in multiple directions the fibre can be woven into a multi-directional sheet (seen as an obvious weave in the sticks surface) or single direction sheets can be layered over each other to create the multi-directional stiffness.

40% of the weight of a composite stick comes from the resin within it. So a stick can’t be 100% carbon. However it can be claimed that 100% of the composite materials in a stick are carbon. Mercian do not believe this gives optimal strength and so always combine the carbon overlay with a composite micro-skeleton made from fibreglass, Kevlar (aramid) and basalt.

Carbon is stiff but brittle. The stiffness means that the energy created by the player when striking the ball – hit / slap – transfers to the ball and is not absorbed by the stick. Maximum energy transfer allowed by the FIH is 98%. But this stiffness means that the stick will not absorb energy on trapping / receiving so needs soft hands!

The brittleness of carbon means that if the fibres are broken (stick tackle / post impact) they will crack and the stick can or will fail. This is not a manufacturing fault.

Other materials can be used in conjunction with carbon to get a positive performance outcome. Special chemicals are used with paints and lacquers to get them to bend to the top layer of carbon and create high-quality graphics.

QUAD CARBON SLEEVE – Q.C.S

Mercian’s QCS technology is based around enhancing the already common braided technology. Braiding as a dictionary definition means:

‘to interweave several strands of (hair, thread,etc); to plait’

By weaving carbon strands together you create a carbon sleeve, this provides 360 degree, seamless strength within a stick. Using such a full-length sleeve creates a softer feel, a lighter weight, but creates exceptional energy transfer and therefore power.

Mercian then overlay the full-length sleeve with 3 more smaller sleeves to offer enhanced protection at the three identified stress points – base of handle, backhand hitting zone and stick ‘heel’. By utilising these four sleeves we create a unique structure for delivery of maximum power and durability.

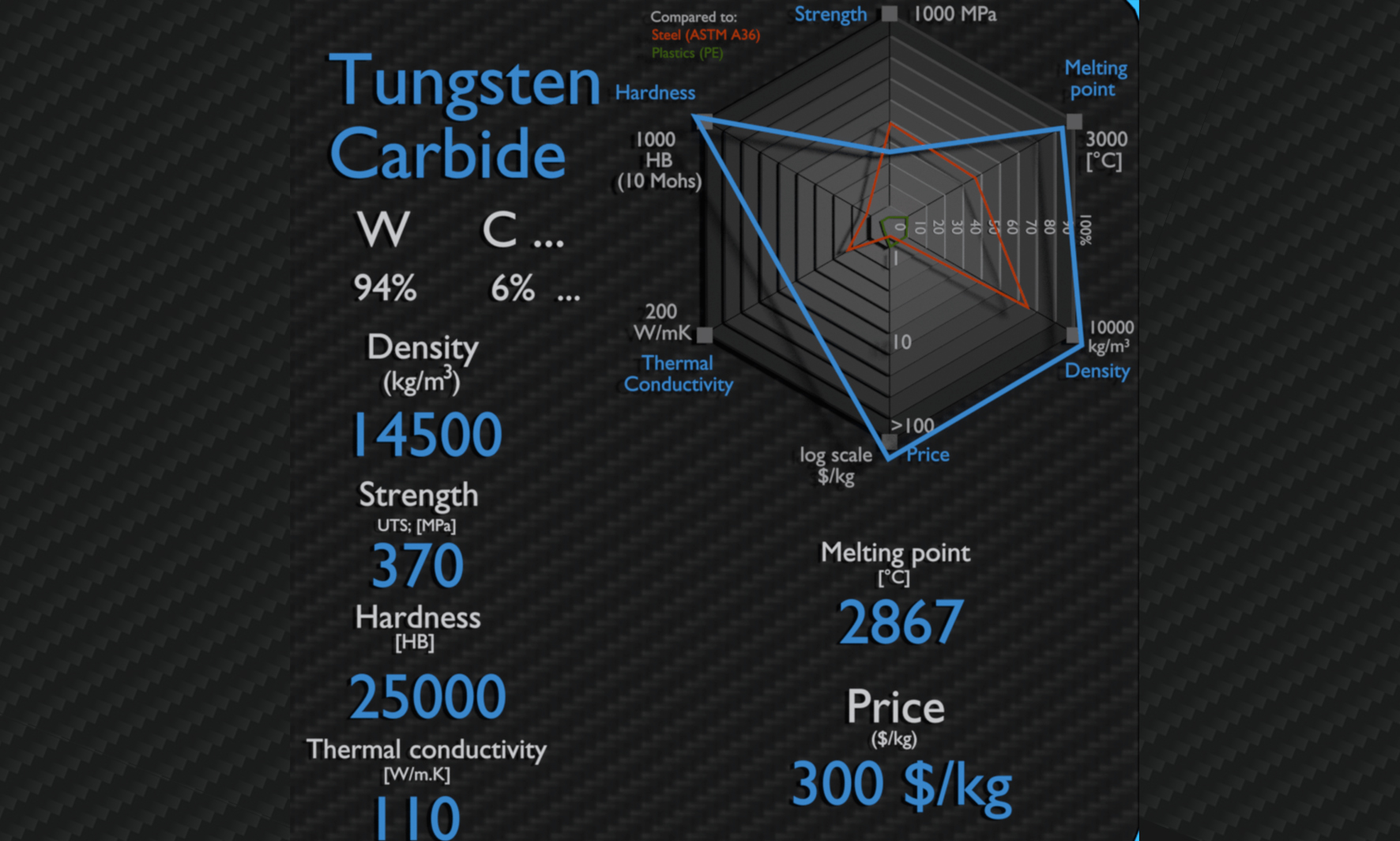

TCDK (Tungsten Carbide Diffused Kevlar)

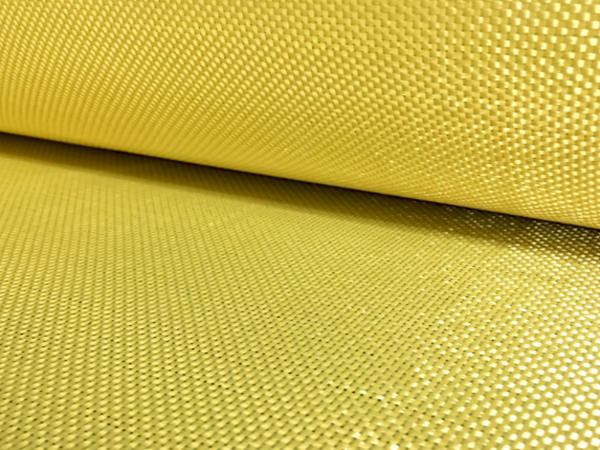

Kevlar is the registered trademark for a para-aramid synthetic fibre, also known simply as ARAMID in other sticks. This high-strength material was first commercially used in the early 1970s as a replacement for steel in racing tires. Typically it is spun into ropes or fabric sheets that can be used as such or as an ingredient in composite material components.

Currently, Kevlar has many applications, including bulletproof vests, because of its high tensile strength-to-weight ratio; by this measure it is 5 times stronger than steel. Tungsten carbide (chemical formula WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine grey powder, Tungsten carbide is approximately twice as strong as steel, For TCDK the fine powder version of WC is diffused through a sheet of Kevlar in the manufacturing process further enhancing the natural characteristics of the material and increasing both its strength and more specifically its durability.

KEVLAR (ARAMID)

Aramid fibres are another material used in the production of hockey sticks. Also known by their trade name of Kevlar they are a heat resistant, incredibly strong synthetic fibre. It was first used commercially in the 1970’s to replace the steel wires used to reinforce racing car tyres.

The threads are drawn from the molten plastic base and have such strength that when interwoven can be used to create bullet proof vests. In a hockey stick they add to the strength and durability of the stick, balancing the brittle nature of the Carbon with shock absorption and creating well bonded hitting surfaces. The weave of the Kevlar has to be carefully monitored so that resin can permeate the layers in the stick allowing for correctly bonded laminates. If a stick starts to come apart (delaminate) it is usually because the resin has not properly travelled through the layers during production, either due to fibres being too tight, resin impregnation being poor initially or the pressure used during production being incorrect.

FIBREGLASS

The fibreglass described within any stick is exactly that, very fine (thin) glass fibres / filaments. Multiple filaments are combined to create a thicker fibre. This is then unwound from a spool (like a big cotton reel), dipped in a resin to make them super sticky and then laid out on a release paper (like grease-proof backing paper) to create single directional sheets of fibreglass. These sheets are then cut into smaller pieces and layered at different angles to create strength in multiple directions.

Whilst fibreglass is strong, it is not as brittle as carbon and therefore forms a fantastic base (micro-skeleton) which absorbs some energy because of its flexibility and over which the Carbon, Kevlar and Basalt can be layered to create high end performance sticks. In our (Mercian) opinion, sticks perform better with a non-carbon base skeleton.

VIBRATION CONTROL

PEIZO-ELECTRIC FIBRES

Piezo-electric fibres are included in all the Evolution sticks they are used to ‘harvest’ the vibrations created in these super-stiff sticks and turn them into heat. The result of this is efficient vibration dampening. Its achieved because the molecules within the material are active, the force applied to them (vibrations) causes the fibres to bend and emit a small electric charge that is dispelled as heat. The technology originally used by Head in tennis, applied those forces through an electrode to counter-act the vibrations (this isn’t present in hockey sticks!)

EVA GRIP

A 1mm thick EVA (Ethylene-vinyl acetate) layer that is applied underneath the supersoft grip on the top three models of sticks. It increases damping and absorbs the vibrations produced by super-stiff carbon sticks.

M-GEL

Creation of perfectly balanced sticks is based on experienced craftsmen, handling the highest quality raw materials and then balancing the final product with the introduction of specific, measured amounts of silicon rubber inside the shaft. This rubber coating, applied at the base of the handle provides a damping effect, reducing vibrations. It is inserted using a long needle and creates a specifically placed rubber layer.

FINISHING

HIGH FRICTION FINISH

EVOLUTION and GENESIS composite sticks feature a silicon-based resin on the face of the sticks not silica-based. The result – increased ball control and skill enhancement. Tiny black rubber particles give texture to the surface. Because they squash on impact they provide a microscopic level of ‘damping’. Perfect for stopping and ball control.

COLD SATIN LACQUER

The final coating applied to a stick is usually purely for cosmetic reasons. The Cold Satin Lacquer applied to the Evolution models actually feels different under a players touch, increasing awareness of temperature and giving the impression of reduced friction for dribbling and stick turn-over.

OTHER FEATURES

NANO-POL

The particles within our resins have been altered at a nano-size level (10 x below microscopic) Instead of using nano-carbon particles, the use of rubberized polymers creates a more flexible but stronger bond between the composite layers. This increases the stiffness of the sticks and reduces de-lamination.

X-FIBRE

A unique lay-up of all the materials used in the top sticks – Fibreglass, Basalt, Kevlar (TCDK) and Japanese carbon to create a specific super-hard panel of processed composite material to enhance the backhand hitting area, helping to generate more power and ball speed.

Products Online

Evolution CKF75

A 75% Carbon, concave face stick. The face ‘cups’ the ball to help with 3D skils, overhead passes and drag-flicking.

Elite Legguards

Now with a unique ‘slide’ skin, aiding smothering and diving. The multiple foam layers give fantastic protection and very high rebound.

Genesis 0.2 Legguards

The Genesis 0.2 range now has the same ‘slide’ skin as the Elite range, reducing surface friction and helping the keeper to execute slide and dive skills.

Mercian have supported me on my Olympic journey, understanding my needs even with the challenges we experience here in South Africa. Sam Mvimbi – South African Olympian (Tokyo 2021)

Email Us

info@mercianhockey.com

Call Us

+44 (0)1483 757677

Write Us

1 Manor Way, Old Woking

GU22 9JX. UK